There are few things more frustrating than arriving somewhere and realizing your gear is soaked through. That’s why choosing the right bag is super important. But finding that right bag can be trickier than we think: some bags say they’re waterproof, others say they’re water resistant, and you might not know what either term really means, let alone what you need.

Don’t worry. We’re here to help. We’ll explain the difference, look at all the variables, and give you some tried and true recommendations, so you can nail your bag of choice.

What's the difference?

The difference between waterproof and water resistant seems obvious. It’s right in their names. Waterproof means water won’t get through the bag. Water resistant means the bag will hold up against water but, at some point, water will get through. That’s all true but all too simple. There are degrees of water resistance and waterproofness. So, to know what you need, you need to know how everything works.

Let’s dive into the differences.

What Does Water Resistant or 'Weatherproof' Mean?

Water resistance comes down to a bag’s materials and how those materials are put together. If any element of the bag can let water in, then it’s no longer waterproof. But it can still be pretty water resistant.

The Material

Let’s start with the fabric. The most common fabrics are nylon, polyester and cotton. These are measured in Denier. One yarn of the material is about one denier. The higher the denier count, the heavier the yarn.

So if your bag is made of 400D nylon, then each of the fibers is made up of 400 yarns of nylon. And so you'd think the more dense the material, the less water will get through, right? Not necessarily true.

600D nylon will repel water better than 1680D nylon. The super high Deniers, although thicker in fibers, actually have larger gaps (but I digress, we could write a whole post on Denier!).

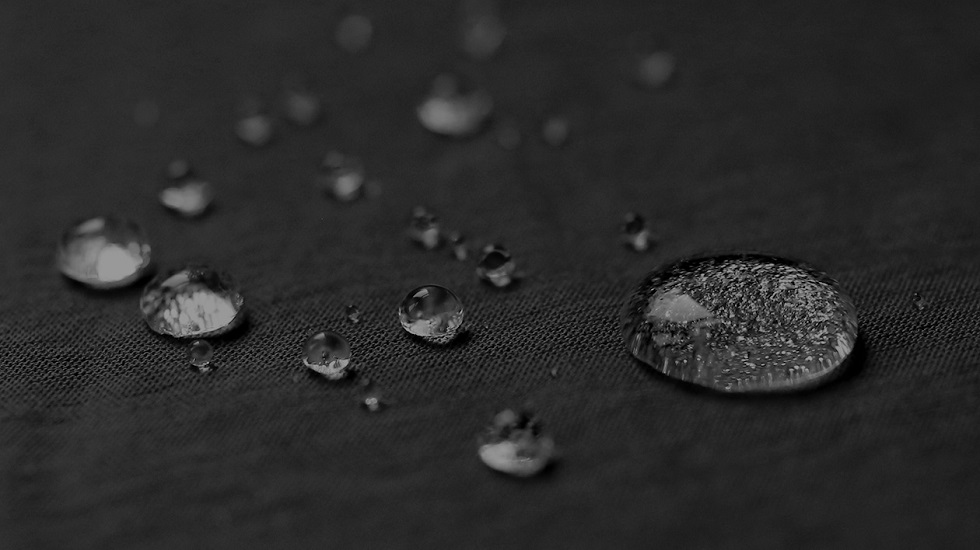

So, even when the material is woven tight, water can still seep through. Water molecules are small, after all. If the water pressure is high enough — that is, if it’s exerting enough force on the bag — water could make its way through the pores in the material.

So you really need something with a protective backing or coating.

"If the water pressure is high enough — that is, if it’s exerting enough force on the bag — water could make its way through the pores in the material."

Coatings of polyurethane (PU), polyvinyl chloride (PVC), or thermoplastic elastomers (TPE) to the back side of fabric can help stop water getting through. Also a Teflon or good ol’ fashioned wax coating can be added to the surface to help water bead up and roll off.

Every little bit helps.

The Construction

You can have all the waterproof fabric you like but it won’t be a waterproof bag if it features your standard zippers or stitching. Water will get in. Construction counts.

Beware of fancy marketing where they advertise "made with waterproof materials" in a way that makes the entire bag appear to be waterproof. A bag can be made with 100% waterproof materials, but still let water in like a sinking ship if constructed with traditional methods.

Your standard zipper has small openings between the teeth. Water that hits those teeth, be it via eerily accurate rain or submersion, will get through. Some bags provide splash guards or use water-resistant fabric to cover the zippers. Others use water-resistant or waterproof zips.

Beware, occasionally brands will advertise their zippers as "waterproof zippers", when they are simply water resistant zippers. Waterproof zippers are very difficult to pull open/close, require maintenance/lubrication, and are very expensive (a great example: check out the main zip on the Patagonia Stormfront).

Pro-Tip: if the bag is sewn and they are advertising a "waterproof zipper," chances are that the zipper is water resistant only. Using a waterproof zipper on a non-waterproof bag just wouldn't make any sense (cost or function).

Next up is how the bag is put together. Check the seams. See needle holes and stitching? That means water has a potential means for ingress. Those holes might be sealed with silicon but seals can break down. Seam taping can help but it’s not perfect. Stitching can fray.

What Does Waterproof Mean?

If your bag is waterproof you can submerge it underwater for a long time and, once you take it out of the water and open it up, everything inside will be bone dry. No water will have penetrated the bag.

Simple.

Every inch of the bag needs to keep water out. It means it’s made from material with pores so small no water molecule can pass through or, ideally, material that doesn’t have pores at all. It means construction that doesn’t involve needle holes — even if you seal those holes, the seals could break down and water could get in.

Construction

Every element of a bag needs to be waterproof for a bag to actually be waterproof. Not just the zipper or the joints or the material. Everything. And, as we’ve seen, that means taking a lot of things into consideration.

Once you have a material with pores so microscopic water can’t get through — or, ideally, material without any pores at all — you have to join that fabric together in a particular way.

Ultrasonic Welding (or RF Welding) is the most common way to go about that. It’s difficult and, despite being “the most common way” of going about this, still quite rare in the scheme of things.

Two panel edges of a material (made from thermoplastic or containing a thermoplastic coating) are carefully aligned and then held together using pressure (via a die). At this point, the RF welding machine emits high level ultrasonic sound waves at the seam (directly focused through the die). The energy from the sound waves activates the material at a molecular level, creating a high level of energy which moves the molecules around rapidly, resulting in heat that permanently bonds the two panels together.

The two panels are technically no longer two panels, they have been fused together and are now one panel. Generally speaking, the bonded area is actually stronger than the mother material. No holes required whatsoever.

These Ultrasonic Welding machines are (very) expensive. The highly trained technicians who use these machines are expensive. Only certain materials can be used and you guessed it... they are also expensive. That means the result is expensive.

You can also expect fewer access points in the bag too. The fewer ways you have in, the fewer ways water has in. That could mean one or two waterproof zips (which, again, are more expensive than water-resistant zips) and roll-tops that cover the access point with a fold or two.

Basically, making a waterproof bag is costly and particular. They require a certain methodology and certain functional and aesthetic sacrifices. That doesn’t mean they’re unattractive. It just means you might not get exactly what you want if you decide to go all in on waterproofing.

The Bottom Line

In all honesty, 99% of individuals do NOT need waterproof bags for EDC/work/travel.

Waterproof bags should be reserved for the rare 1% that see prolonged downpours every day in their lives OR for individuals who are purchasing an activity specific bag (like an upcoming whitewater rafting trip etc.)

The Sono Studio Team